Thursday, January 28, 2021

Measurements

Major Overhauling

(In

Co-Ordination with Electrical, Civil, Instrumentation departments)

INITIAL

MEASUREMENTS:

Rotor

"K" Position

Casing Split (half joint) Clearance

Bearing

pedestal Clearance

Casing bolts

length measurement (Before & After removal)

Coupling Bolts

length measurement (Before & After removal)

Steam

admission flange bolts length measurement (Before

& After removal)

Pedestal

clearance

Pedestal seal

clearance

Bearing seal

clearance

Journal

bearing clearance

Gland seal

clearance

Thrust bearing

clearance

Thrust bearing

seal clearance

Main oil pump

seal clearance

Initial

Alignment

SEQUENCE

OF DISMANTLING:

Remove Turning

Gear unit

Remove

coupling cover

Remove

coupling bolts

Remove Bearing

pedestals

Remove Front

& Rear gland boxes

Remove casing

bolts by heating (by special bolt heater)

Remove steam

admission flange bolts

Remove thrust

bearing housing

Remove HP, LP,

Throttle (ESV) Valve actuators.

Wednesday, January 20, 2021

Over View

STEAM TURBINE

Principle: Pressure energy is converted in to kinetic energy and get mechanical work done.

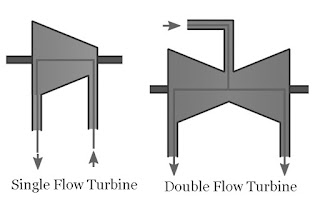

Major Classification:

- Impulse Turbine

- Reaction Turbine

- Impulse Reaction Turbine

Double Flow

About me

A giant ship engine failed. The ship’s owners tried one expert after another, but none of them could figure but how to fix the engine.

Then they brought in an old man who had been fixing ships since he was a young. He carried a large bag of tools with him, and when he arrived, he immediately went to work. He inspected the engine very carefully, top to bottom.

Two of the ship’s owners were there, watching this man, hoping he would know what to do. After looking things over, the old man reached into his bag and pulled out a small hammer. He gently tapped something. Instantly, the engine lurched into life. He carefully put his hammer away. The engine was fixed!

A week later, the owners received a bill from the old man for ten thousand dollars.

“What?!” the owners exclaimed. “He hardly did anything!”

So they wrote the old man a note saying, “Please send us an itemized bill.

The man sent a bill that read:

Tapping with a hammer………………….. $ 2.00

Knowing where to tap…………………….. $ 9,998.00

Effort is important, but knowing where to make an effort makes all the difference!

-

I am being a Mechanical engineer with 40 years of experience in maintenance of production line and Power plant machines. During my service...

-

STEAM TURBINE It is a thermodynamic machine . Principle: Pressure energy is converted in to kinetic energy and get mechanical work done. S...

-

Major Overhauling (In Co-Ordination with Electrical, Civil, Instrumentation departments) INITIAL MEASUREMENTS: Rotor "K" Pos...